During optimization PI Expert automatically chooses all components required for the power supply being designed. Once PI Expert receives the input and output specifications, the optimization process iterates on multiple parameters and produces several results. It then ranks these results and presents the top solutions based on the specifications provided.

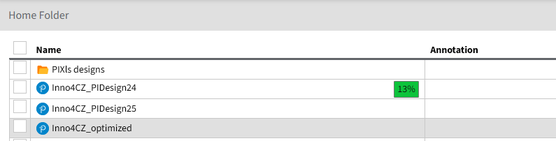

You can freely log out of PI Expert, the optimization process will continue. Optimization progress is displayed in the File manager.

During the optimization process, PI Expert makes so many simulations as calculated by the initial solution set.

Once PI Expert receives technical data about the inputs and outputs, the optimization process is repeated taking into account various parameters, and several results are returned. The results are then classified and the best solutions are given based on the provided technical data. Optimization takes some time, since the program needs to evaluate all user-specified conditions for device operation.

Use the Active design > Start optimization menu or the button on the toolbar

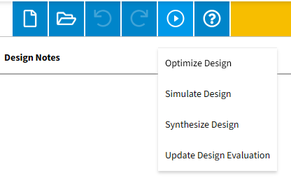

User can configure optimization in the “Optimization Settings” window.

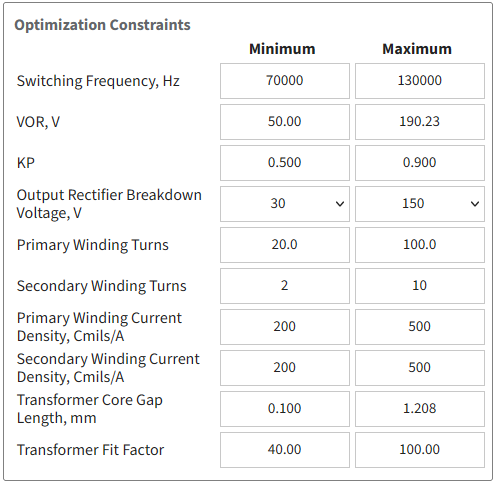

Optimization constraints.

The optimization Constraints are the maximum and minimum bounds of the optimization parameters such as, Switching Frequency, VOR, KP, Maximum Flux density, number of Primary Turns and set a threshold of acceptance for the bobbin Fit Factor (the percentage of the bobbin height occupied by the windings). The Optimization will attempt to find one or more solutions which satisfy these constraints. If the optimization does not find a solution, releasing the constraints may help.

In the “Optimization Constraints” window, user can set the necessary parameters for the selected values within the boundaries of which the design will be optimized.

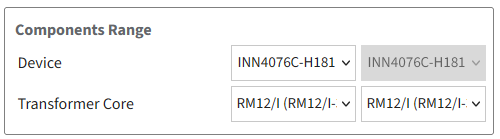

Components Range.

In the Components Range area, user can limit devices and cores list taken into account during optimization.

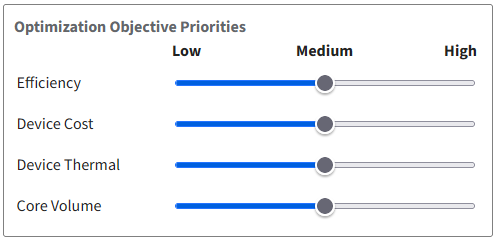

Optimization objective priorities

By default, the optimization attempts to find a balanced solution in terms of efficiency, transformer size and cost and thermals of primary switch and secondary rectifier. By means of the sliders placed in this section, you can now set incremental levels of priority at each of the objective function terms. For example, if the highest level of priority is given to the efficiency term, you can expect a more efficient design which in turn might use a more expensive controller and/or SRFET. On the contrary if the highest is given to cost and lower priority to all the other terms, you can expect a resulting design which presents a cheaper device as well as a cheaper SRFET. This will result in a more cost effective design with some impact on overall efficiency of thermal performance.

The following types of optimization are available from Optimization objective form:

-Device cost. During the cost optimization process a number of designs using different combinations of cores, secondary turns, secondary output stacking configuration and output diodes are scored based upon criteria internal to the software. A list of the top scoring designs is maintained throughout the optimization process. Upon successful completion, the list of top designs is displayed. You can then choose the design which you believe to be the most appropriate for your application.

-Efficiency. The PI Expert efficiency optimization routine will first find the smallest PI device capable of delivering the power specified. The software will then reduce the peak to ripple primary current ratio (KP) in an attempt to make the design more continuous. This decreases the peak primary current (IP) which will decrease the peak and RMS currents in both primary and secondary windings. This reduction in current magnitudes increases the overall supply efficiency due to reduced conduction losses.As in cost optimization a number of designs are then examined and passed on to the optimization process. PI Expert then retrieves a list of the best scoring designs and then displays it.

-Device thermal. The PI Expert calculates thermal characteristics during simulation trying to find the most optimal solution.

-Core volume. The PI expert is trying to find the core with optimal electrical characteristics. And also trying to reach 100% fit of windings into the bobbin window.

In the optimization priorities window, the user can choose which priority indicators the design should be optimized for. Obviously, the higher the efficiency and better the thermal characteristics, the higher the assembly price will be, and vice versa.

Top Solutions to Summary - The number of the design solutions PI Expert displays when optimization is complete.

Initial solution set - precalculated number of design simulations during optimization process based on the constraints.

PI Expert gives you the Optimization Status at the bottom of the main window.

-Simulation in progress.

-Simulation complete!

-Design Update Required!

-Canceled.

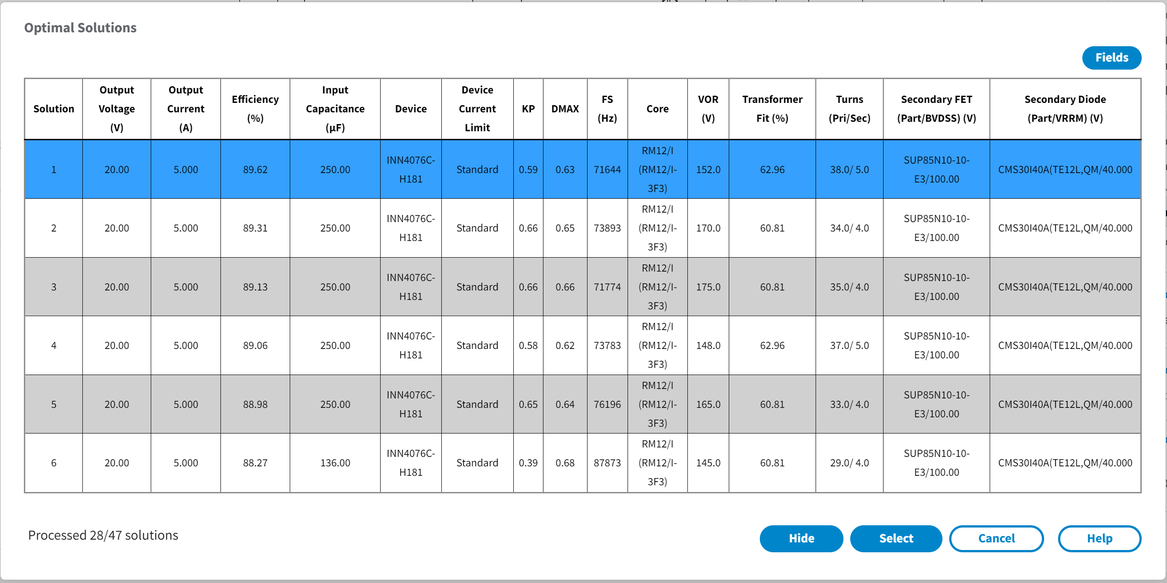

The Optimal Solutions dialog

displays the list of most optimal designs that PI Expert has produced after the optimization process. The Optimal Solutions dialog allows you to choose the solution you prefer based on the information available. The number of solutions found is shown in the lower left corner of the window. Choose the solution and click Select. You can cancel the optimization results and open the created design without and return to the previous state, before optimization, by clicking the Cancel button.

displays the list of most optimal designs that PI Expert has produced after the optimization process. The Optimal Solutions dialog allows you to choose the solution you prefer based on the information available. The number of solutions found is shown in the lower left corner of the window. Choose the solution and click Select. You can cancel the optimization results and open the created design without and return to the previous state, before optimization, by clicking the Cancel button.